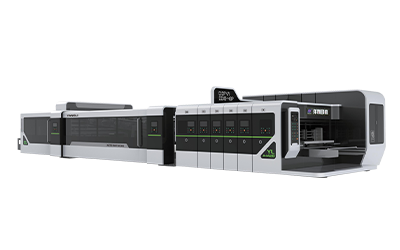

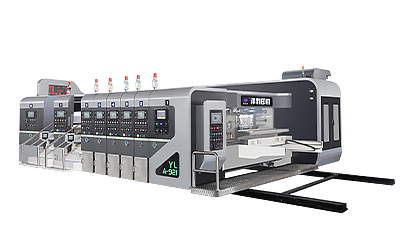

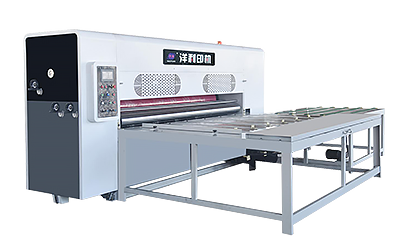

CZYL-ACL

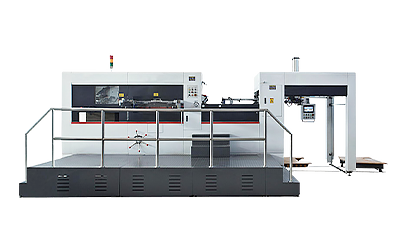

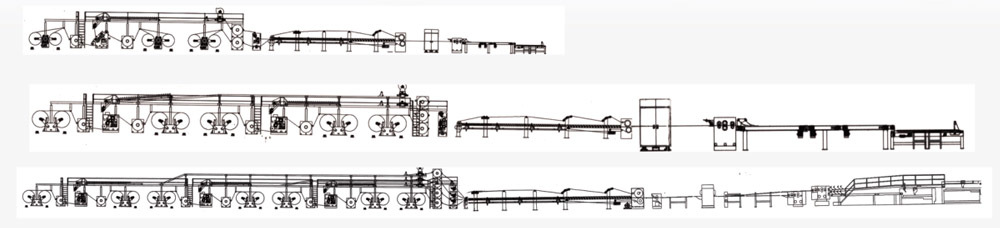

High speed 3/5/7 layer corrugated cardboard production line

Contact CZYLPACK for Shipping, delivery, and payments information.

Products Category

Tag list

- 产品描述

-

Working principle

Tile line is the abbreviation of corrugated cardboard production line. It is a streamline line consisting of pressing, corrugating, gluing, bonding, grading, papermaking, and code output. Such as single corrugated paper production line is made of web frame, single-sided corrugated cardboard machine, composed of rotary paper cutting unit, using web material and potato or corn starch adhesive, single-sided corrugated board continuous production and cut into the required specifications, production of cardboard no longer dry or dry, and glue machine or laminating machine with the use of, can produce more than three layers of corrugated cardboard.

Equipment configuration and technical description

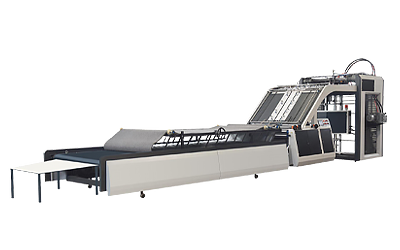

Machine name: five-layer corrugated board production line

Specifications and models Device name Unit Number Remarks ZJ-V5B Full hydraulic pressure

Paperless frameset 5 Spindle Φ 240, hyperbolic heavy rocker arm, tooth type paper holder, multipoint brake, hydraulic drive lift, left and right translation, to medium.

The guide rail length is 6,000 mm, and the trolley is welded with 10mm medium plate.Paper bike set 10 RG-1-800 Surface paper preheating cylinde set 1 Roller ¢900 mm, including pressure vessel certificate. Electric adjustment package angle. The wrapping angle can adjust the heating area of paper within 360 range RG-1-800 Core paper preheating cylinder set 1 Roller ¢900 mm, including pressure vessel certificate. Electric adjustment package angle. The wrapping angle can adjust the heating area of paper within 360 range SF-320C Adsorption

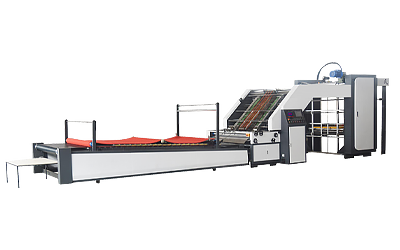

Single sided machineset 3 Corrugated main roller ¢320 mm, material using tungsten carbide. Imported main bearing, PLC automatic glue control, man-machine interface touch screen, paper break automatic stop pressure relief, steam heating mode RG-3-800 Triple preheater set 1 Roller ¢900 mm, including pressure vessel certificate. Electric adjustment package angle. The wrapping angle can adjust the heating area of the paper in the range of 360. GM-18 Secondary Gumming Machine set 1 Cots 268 mm. diameter Each layer of independent frequency conversion motor drive, PLC adjust the glue clearance and man-machine interface. ZDF Transport Bridge cover 1 Main beam 200 mm channel steel, independent frequency conversion motor drive paper transfer, adsorption tensioning. Electric correction SM-F Double sided machine cover 1 The frame 400 mm national standard channel steel, chromium plating hot plate 600 mm *18 block, the entrance ¢400 mm hot cylinder causes the surface paper to raise the temperature extremely fast 6 groups to touch the whole process with 18 pcs hot shoes plate design structure. PLC automatic control pressure plate. Temperature display, frequency conversion motor. NCBD Computer

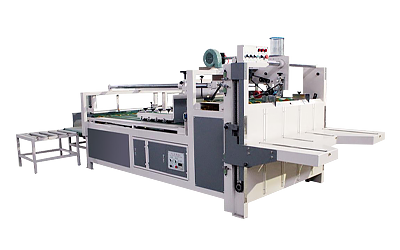

thin knife

Cutting

Indentation

machineset 1 Tungsten alloy blade, five-knife eight-wire type,

electric row knife, electric lift left and right movement with single shaft settingNC-150 Computer

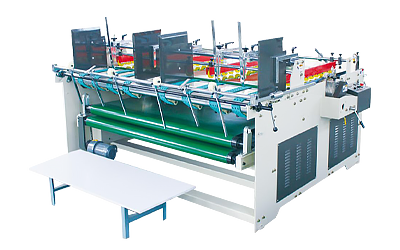

Spiral

Knife

Transverse

Cutting

Machineset 1 Full AC Servo Control, Energy Storage Brake, Spiral Knife Structure, Oil-immersed Gear Drive ,10.4 inch Touch Screen Display with memory function upto 999 DM-LM Right-angle

stackingset 1 Servo drive platform lift, three-stage frequency conversion transport, automatic point stacking discharge, imported high-strength belt output, paper side standard conveyor. ZJZ Rubber

station

systemcover 1 Pipeline customer self-provided. The device consists of carrier tank, main tank, storage tank, rubber pump and rubber pump. QU Air supply

systemset 1 Equipped with 0.6 m³ gas storage tank 1. Pipeline customer self-provided. ZQ Vapour

systemcover 1 Steam components including piping valves, trap valves, meters, etc. in equipment, customer-owned heat source and piping DQ Electrical

control

cabinet

systemcover 1 Electronic control system: adsorption single-sided machine, driving part, electric thin knife machine, double-sided machine, glue coating machine all adopt frequency conversion motor, Delta frequency conversion control system. The operation interface is simple and convenient, the speed display control cabinet is equipped with each unit speed display, the unit calls, the emergency stop function.

The main relay adopts French Schneider famous brand products.Main technical parameters and requirements of the production line

Model: YL- 120-1800-Type III five-layer corrugated board production line:

1 Maximum production

paper width1800mm Design Production

Speed120m/min 2 Three-tier working

speed80-120m/min Five-tier working

speed80-120m/min 3 Precision of Longitudinal

Cutting Paper±1mm Cross cutting

accuracy±1mm Rem

arksThe The speed indicator must be met with:Production width of 1800mm,Meet the following paper standards and ensure that the surface temperature of the equipment is at 175℃ Surface paper

indicators80-250≥ ring pressure index (N.m/g) Core paper index

indicators80-175 g/m2 ring pressure index (N.m/g)≥5.5(moisture content 8-10%) Paper finger 80-250 g/m2 Ring pressure index (N.m/g)≥6(moisture content 8-10%) 4 Shurang type

combination5 Steam

requirementsMaximum pressure of

16kg / cm2Common pressure is

10-12kg / cm2The dosage was

4,000 kg / Hr6 Electricity

requirementsAC380V 50Hz 3PH Installed capacity

is 250KWCommon power

is 150KW7 Compressed air The maximum pressure

is 9kg / cmCommon pressure: 4-8kg / cm2 1m3/minThe amount was 1 m3/min 8 Space usage Lmin75m * Wmin10m * Hmin5m (actually subject to the audited drawings provided by Party B) Customer self-provided part

SteaSteam heating system: it is recommended to have a 4000 Kg / Hr steam boiler with a pressure of 1.25 Mpa steam pipe. Air c Air compressor, air pipeline, rubber liquid conveying pipeline The Power supply and wire are connected to the operation cabinet and line pipe. Water sources, water pipes, buckets, etc

WateCivil works for water, electricity and gas foundation plane installation.

InsTest run with base paper, corn (potato) starch, industrial caustic soda, borax and other materials.

TestOil, lubricating oil, hydraulic oil and lubricating grease are used for the equipment.

OilFood and accommodation for installation and commissioning personnel. And provide the installation workers to cooperate with the installation.

Food

Our Company

Dongguang Yangli carton machinery Co.,Ltd. is located in the middle of bohai economic circle, north Beijing and Tianjin, south according to Jinan, land and water transportation is very convenient, is a modern professional production of carton packaging machinery, printing machinery enterprises.

The company has strong technical force, advanced production and testing equipment, with professional technical and management personnel and high-quality sales team. We adhere to the quality of survival, science and technology for development, learn from others, integration of the essence of mechanical research at home and abroad, to ensure that customers supporting production of stable quality, reasonable price, new efficient packaging machinery and equipment.

Machining Center

Packing & Delivery

Yangli company can stand out in many carton machinery enterprises, because of its strict and perfect management system. The company has established a one stop management system from production--inspection--debugging--sales--after sales service, strict control of each machine, truly make users satisfied and assured.

Company Exhibition

The product design and manufacture of our company all comply with European standards. The produced carton equipment has been exported to over 60 countries and in more than 20 provinces of China. Sales offices and after-sales service outlets are set up in each place to provide customers with guarantee services.

Transport

FAQs

Q:Are you a factory or a trading company?

We are a direct manufacturer which is located in Dongguang county, Cangzhou city, we mainly manufacturing corugated carton box printing slotting die cutting machine, folding gluing stitching machine, single facer corrugated machine etc. Welcome to visit our factory!

Q:How do you ensure your quality?

1. Trustworthy and long-term cooperative raw material suppliers;

2. Skilled&experienced engineer&workers;

3. Mature QC system;

4. Specially-assigned merchandiser;

5. Advanced production workshop.

Q:How about your after-sale service?

1. Special after-sale team will be 24/7 online;

2. Can guide the installation door-to-door;

3. One-year warranty for spare parts.

Q:How many languages does your machine support?

Our machine supports all the languages.

Q:How long it will take to produce machine?

Delivery time largely depends on the machine type, for some small machine like manual stitching machine, manual banding machine etc, usually we have stock available. But for the large machines like carton printing die cutting machine, automatic stitching machine etc, it usually takes around 35-50 days to produce.

Contact Us

CZYL-ACL

High speed 3/5/7 layer corrugated cardboard production line

Contact CZYLPACK for Shipping, delivery, and payments information.

Products Category

Tag list