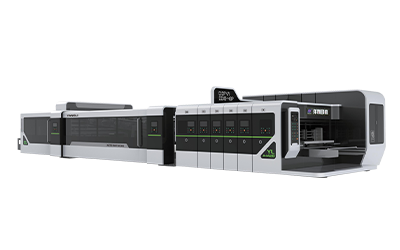

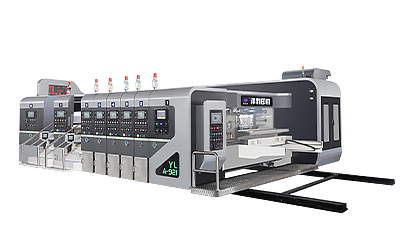

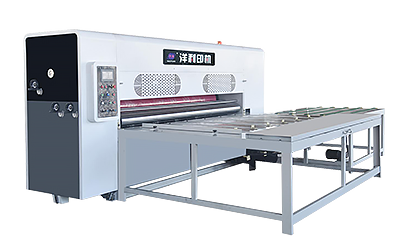

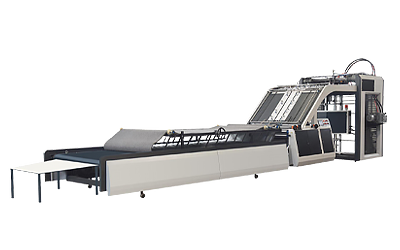

CZYL-LM

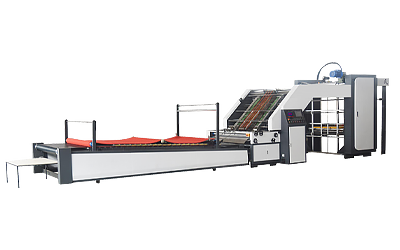

3 layer automatic laminating machine

Contact CZYLPACK for Shipping, delivery, and payments information.

Products Category

Tag list

- 产品描述

-

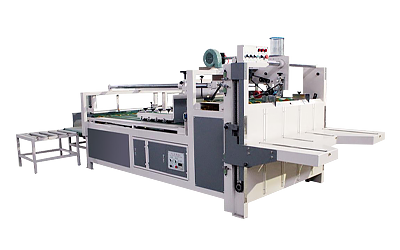

Down folding and gluing machine

◆ This machine adopts a unique compression spring front gauging design to effectively reduce the mechanical failure rate and ensure accurate fit and positioning with intelligent control.

◆ This machine adopts frequency conversion speed regulation. PLC centralized control, analog-to-digital conversion, and operation control are accurate.

◆ The base paper adopts dual servo control to achieve timeliness and accuracy from the base paper to the front gauges, ensuring the accuracy of the machine under the condition of adjustment of the machine.

◆ The steel roller has undergone balance processing and testing, and combined with the tight assembly process, the stability of the machinery is effectively improved. In addition, the main transmission uses a time-gauged belt transmission, and the bottom paper part directly sections the air and feeds the paper, which effectively improves the operation accuracy and speed of the machinery.

◆ The page control system is adopted and the glue is automatically circulated, which greatly reduces the labor intensity.

◆ This machine adopts all ISO9001 materials for inspection, high quality and strong durability. Imported parts of key parts such as bearings.

◆ Powerful Feida paper feeding is equipped with a pre-coded paper device to reduce downtime and improve work efficiency.

◆ This machine is suitable for veneers of 150-450GSM surface paper and A B C D E F waves and three and five-layer paperboard (up to a maximum thickness of less than 10 mm).

Technical parameters

Maximum paper size(W*L) 1450

1300mm*1450mm1650

1300mm*1650mmMinimum paper size(W*L) 470mm*360mm 470mm*360mm Thickness Top-level worksheet 170~800 g/m2 170~800 g/m2 Underlying worksheet 0.5-10mm(B,A,AB,E Flute) 0.5-10mm(B,A,AB,E Flute) Lamination accuracy ±1mm ±1mm Maximum speed 170/Minutes 170/Minutes Power supply 29KW 29KW Size L * W * H 15000mm*2200mm*2500mm 15000mm*2400mm*2500mm The height of the base paper 400mm 400mm The height of the top paper 1800mm 1800mm Machine weight 7.6T 8.2T

Our Company

Dongguang Yangli carton machinery Co.,Ltd. is located in the middle of bohai economic circle, north Beijing and Tianjin, south according to Jinan, land and water transportation is very convenient, is a modern professional production of carton packaging machinery, printing machinery enterprises.

The company has strong technical force, advanced production and testing equipment, with professional technical and management personnel and high-quality sales team. We adhere to the quality of survival, science and technology for development, learn from others, integration of the essence of mechanical research at home and abroad, to ensure that customers supporting production of stable quality, reasonable price, new efficient packaging machinery and equipment.

Machining Center

Packing & Delivery

Yangli company can stand out in many carton machinery enterprises, because of its strict and perfect management system. The company has established a one stop management system from production--inspection--debugging--sales--after sales service, strict control of each machine, truly make users satisfied and assured.

Company Exhibition

The product design and manufacture of our company all comply with European standards. The produced carton equipment has been exported to over 60 countries and in more than 20 provinces of China. Sales offices and after-sales service outlets are set up in each place to provide customers with guarantee services.

Transport

FAQs

Q:Are you a factory or a trading company?

We are a direct manufacturer which is located in Dongguang county, Cangzhou city, we mainly manufacturing corugated carton box printing slotting die cutting machine, folding gluing stitching machine, single facer corrugated machine etc. Welcome to visit our factory!

Q:How do you ensure your quality?

1. Trustworthy and long-term cooperative raw material suppliers;

2. Skilled&experienced engineer&workers;

3. Mature QC system;

4. Specially-assigned merchandiser;

5. Advanced production workshop.

Q:How about your after-sale service?

1. Special after-sale team will be 24/7 online;

2. Can guide the installation door-to-door;

3. One-year warranty for spare parts.

Q:How many languages does your machine support?

Our machine supports all the languages.

Q:How long it will take to produce machine?

Delivery time largely depends on the machine type, for some small machine like manual stitching machine, manual banding machine etc, usually we have stock available. But for the large machines like carton printing die cutting machine, automatic stitching machine etc, it usually takes around 35-50 days to produce.

Contact Us

CZYL-LM

3 layer automatic laminating machine

Contact CZYLPACK for Shipping, delivery, and payments information.

Products Category

Tag list