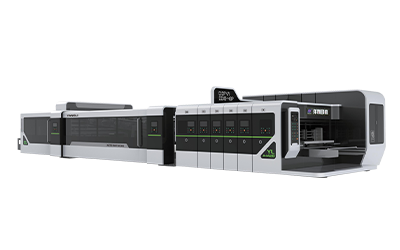

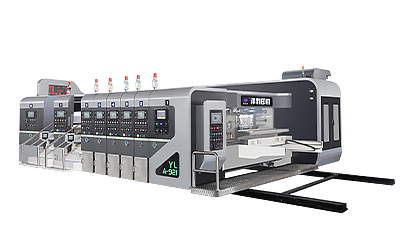

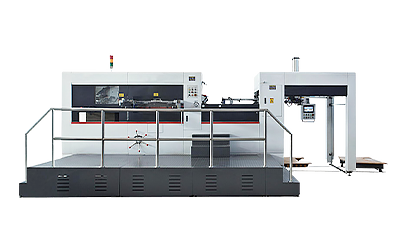

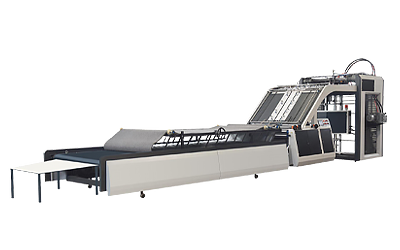

CZYL-A

High speed lead edge printing rotary die cutter & full PLC control machine

Contact CZYLPACK for Shipping, delivery, and payments information.

Products Category

Tag list

- 产品描述

-

Uses and features

★ Advanced adsorption front feeding system, simple operation, high precision.

★ 200 groups of installed 7 in true color touch screen, which can be preset order, the order query, zero order entry, the machine synchronous zero, phase automatic/manual adjustment, machine parameters management, lift fall edition distributing manual/automatic control, automatic display production quantity and production speed and to set production quantity.

★ All roll material made of high-quality steel, hard chrome plating, surface grinding. Drive gear: premium alloy steel, heat-treated and ground.

★ All roll material are of high quality steel, hard chrome plating, surface grinding. Drive gear adopt high quality alloy steel, after heat treatment, grinding.

★ Clearance adjustment self-locking worm gear box with high precision, and is equipped with three stem disc handle, convenient and quick.

★ Slot department adjusted by electric control knife axis, vertical and cases each high dimensions.

★ Die cutting speed difference compensation system, the soft roller CAM type horizontal swimming 40 mm, MATS wear uniform and improve the utilization rate of foot pads to reduce the cost.

★ Applied to 3/5/7 layer corrugated and E stare blankly cardboard.

Project 920 922 1224 1228 1426 1628 Max.speed(pcs/min) 300 260 250 200 180 150 Feeding precision(mm) ±1 Min.sheet size(mm) 250×500 340×600 380×600 Max.sheet size(mm) 850×2000 850×2200 1150×2400 1150×2800 1350×2600 1550×2800 Skip sheet size(mm) 1200×2000 1200×2200 1400×2400 1400×2800 1600×2600 1800×2800 Max.printing area(mm) 820×2000 820×2200 1150×2400 1150×2800 1400×2600 1550×2800 Printing precision(mm) ±0.5 Plate thickness(mm) 7.2 Minimum slot

(L×W×H)(mm)220×60×70 250×60×80 250×60×80 Minimum die cutting

(L×W×H)(mm)170×80×80 180×80×80 180×80×80 Max.slot depth(mm) 230 310 370 410 increase the blade,increase the slot depth Slotting precision(mm) ±1 Max.die cutting size(mm) 900×2000 900×2200 1200×2400 1200×2800 1400×2600 1600×2800 Die cutting precision(mm) ±1

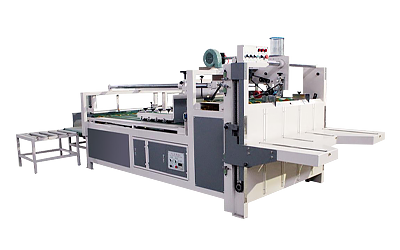

Paper Feeding Department

◆ Adopting three axes (four axis), leading edge roller to send paper, paper feeding is more accurate, and the bending board is easy to be fed;

◆ Can be set to send the board to reduce the pressure of paper roll;

◆ Can be continuous, separate sheets or sheet fed, machine counter to record the number of production;

◆ The leading edge of the cardboard to reduce the mechanical error, so that printing, slotting position is more accurate;

◆ Using variable frequency control of air volume and pressure, in order to adapt to the board thickness and size.

◆ Touch screen is used to adjust the clearance of the side baffle;

◆ High efficiency dust removal and dust removal machine can eliminate the impurities on the surface of cardboard printing, and improve the printing quality;

◆ After the use of gas, electric control, before and after the move, adjust quickly;

◆ With a strong cylinder main lock, so that the machine running more smoothly;

◆ Host motor start protection device - the machine is not locked in place, the host can not boot operation.Printing Department

◆ The hanging plate printing system is adopted, and the exchange plate is convenient to operate, and a foot switch is arranged.

◆ Roller with paper feeding system pressure type automatic lifting device. (feed roller and a printing plate contact down, stop Stop feeding roller and a printing plate separation) rise.

◆ Printing roller circumferential adjustment mechanism using planetary gear manufacturing.

◆ Printing phase using touch screen control and electric digital 360 degree adjustment (operation, stop state can be adjusted)

◆ Inking roller adopts high precision hard chromium roller; optional ceramic roller.

◆ Rubber roller with steel tube surface coated with wear-resistant rubber, the middle and high special grinding, ink effect is good. According to customer needs Seal scraper system to be selected.

◆ The printing phase fixing device adopts an electromagnetic clutch brake mechanism. The rotation of the machine is limited, and the fixed point of the original gear position is maintained.

◆ Control panel is equipped with touch screen, easy to operate.

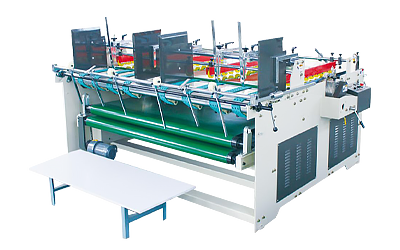

Grooving Department

◆ Single-axis double-cutting three-voltage wire groove or double-cutting double-cutting wire groove, using servo independent drive.

◆ Grooved tool holder horizontal movement adjustment mechanism: Use a screw rod to match the linear optical axis of the linear guide rail to make the movement flexible and accurate. The upper tool holder and the lower tool holder are synchronously linked with the transmission shaft, which makes the tool life longer.

◆ With the screw rod structure, the middle knife can be moved to any position freely, and the double-piece molded carton size can be automatically set.

◆ Adopt a 1:1 large pressing structure, which has low requirements for cardboard conditions and does not damage the cardboard, making the pressing effect more perfect and the molding more beautiful.

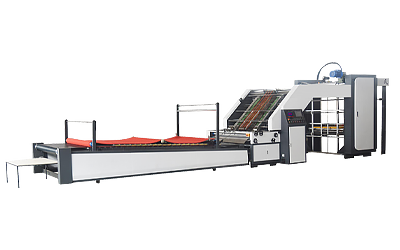

◆ The damage wheel and grooved tool holder are moved horizontally, and are controlled by computer and electric.Die - Cutting Department

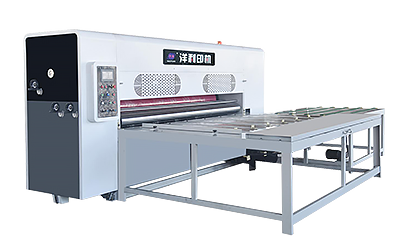

◆ Rubber pad roller: centrifugal casting steel simplified, computer dynamic balance correction, surface grinding, hard chrome plating.

◆ Die cutting roller: centrifugal casting steel simplified, computer dynamic balance correction, surface grinding, hard chrome plating.

◆ (Optional: plate free die cutting channel steel knife die, do conventional box slotting, cutting Angle use with box high synchronization adjustment function).

◆ Die-cutting roller phase and axial adjustment, phase adjustment using planetary gear structure, PLC touch screen control and electric digital 360 adjustment, axial and horizontal movement using.

◆ PLC touch screen and electric digital adjustment, adjustment range of soil 15mm.

◆ Cots cutting repair mechanism, rubber pad can be reused for many times, can greatly save the use of cost.

◆ Differential compensation device, automatic adjustment of the foot roller rotation, so that the mold cutting of the carton and the shape of the knife die completely consistent.

◆ Rubber pad roller mechanical transverse +40m swimming device, improve the service life of die-cut rubber pad.

◆ This unit independent servo synchronous drive, eliminate the cumulative error, according to the range of die cutting speed and paper feeding, printing to keep consistent.

Our Company

Dongguang Yangli carton machinery Co.,Ltd. is located in the middle of bohai economic circle, north Beijing and Tianjin, south according to Jinan, land and water transportation is very convenient, is a modern professional production of carton packaging machinery, printing machinery enterprises.

The company has strong technical force, advanced production and testing equipment, with professional technical and management personnel and high-quality sales team. We adhere to the quality of survival, science and technology for development, learn from others, integration of the essence of mechanical research at home and abroad, to ensure that customers supporting production of stable quality, reasonable price, new efficient packaging machinery and equipment.

Machining Center

Packing & Delivery

Yangli company can stand out in many carton machinery enterprises, because of its strict and perfect management system. The company has established a one stop management system from production--inspection--debugging--sales--after sales service, strict control of each machine, truly make users satisfied and assured.

Company Exhibition

The product design and manufacture of our company all comply with European standards. The produced carton equipment has been exported to over 60 countries and in more than 20 provinces of China. Sales offices and after-sales service outlets are set up in each place to provide customers with guarantee services.

Transport

FAQs

Q:Are you a factory or a trading company?

We are a direct manufacturer which is located in Dongguang county, Cangzhou city, we mainly manufacturing corugated carton box printing slotting die cutting machine, folding gluing stitching machine, single facer corrugated machine etc. Welcome to visit our factory!

Q:How do you ensure your quality?

1. Trustworthy and long-term cooperative raw material suppliers;

2. Skilled&experienced engineer&workers;

3. Mature QC system;

4. Specially-assigned merchandiser;

5. Advanced production workshop.

Q:How about your after-sale service?

1. Special after-sale team will be 24/7 online;

2. Can guide the installation door-to-door;

3. One-year warranty for spare parts.

Q:How many languages does your machine support?

Our machine supports all the languages.

Q:How long it will take to produce machine?

Delivery time largely depends on the machine type, for some small machine like manual stitching machine, manual banding machine etc, usually we have stock available. But for the large machines like carton printing die cutting machine, automatic stitching machine etc, it usually takes around 35-50 days to produce.

Contact Us

CZYL-A

High speed lead edge printing rotary die cutter & full PLC control machine

Contact CZYLPACK for Shipping, delivery, and payments information.

Products Category

Tag list